CNC machining and cold forming

The parts may require mechanical processing after welding in order to comply with all the tolerances necessary for assembly.

We therefore offer the possibility of mechanical processing to complete the supply. This is thanks to a reliable network of subcontractors, all ISO certified.

For example, for the production of steering columns for agricultural machines and for the frames of packaging machines, we work welded carpentry with chip removal machines:

- machining centers with vertical and horizontal axes (maximum pallet size 1200 × 800)

- CNC and multi-spindle parallel lathes.

For our production of the longitudinal members for the frames of the concrete mixers we drill them with a portal cutter and after the bending and welding.

- Moving column CNC milling machine for machining up to 8 meters.

- CNC portal milling machine for machining up to 4.3 meters. ISO50

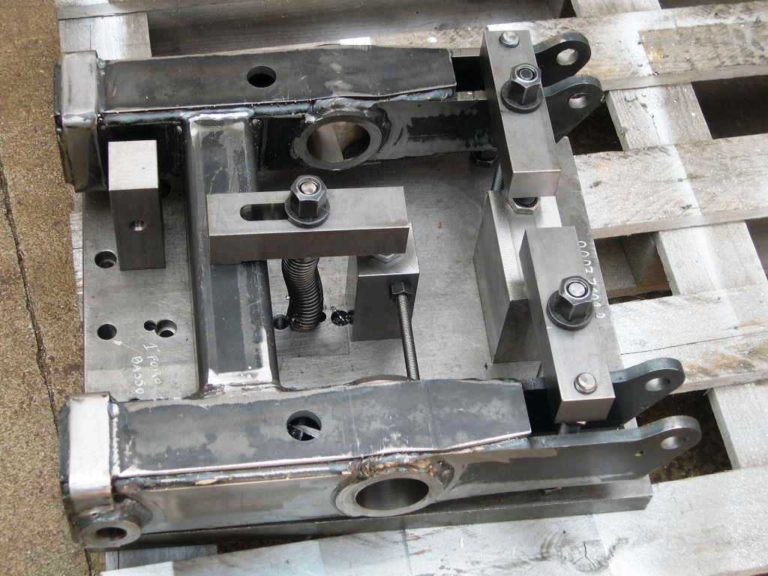

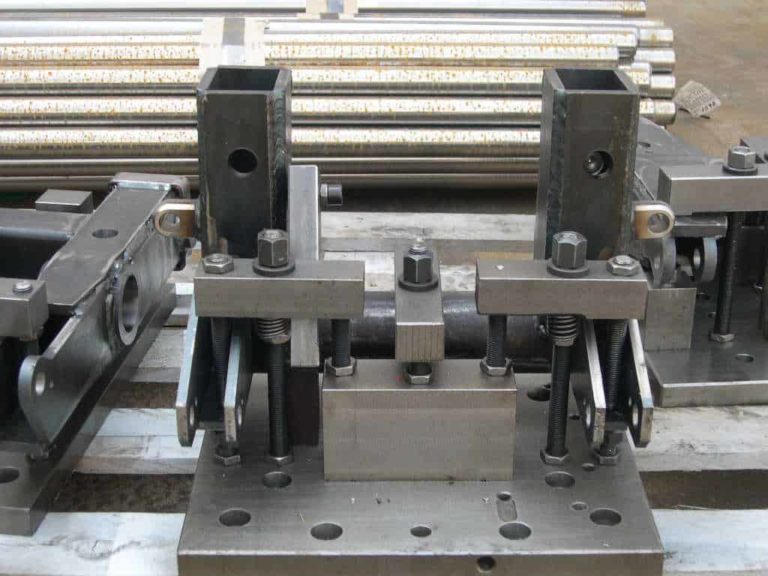

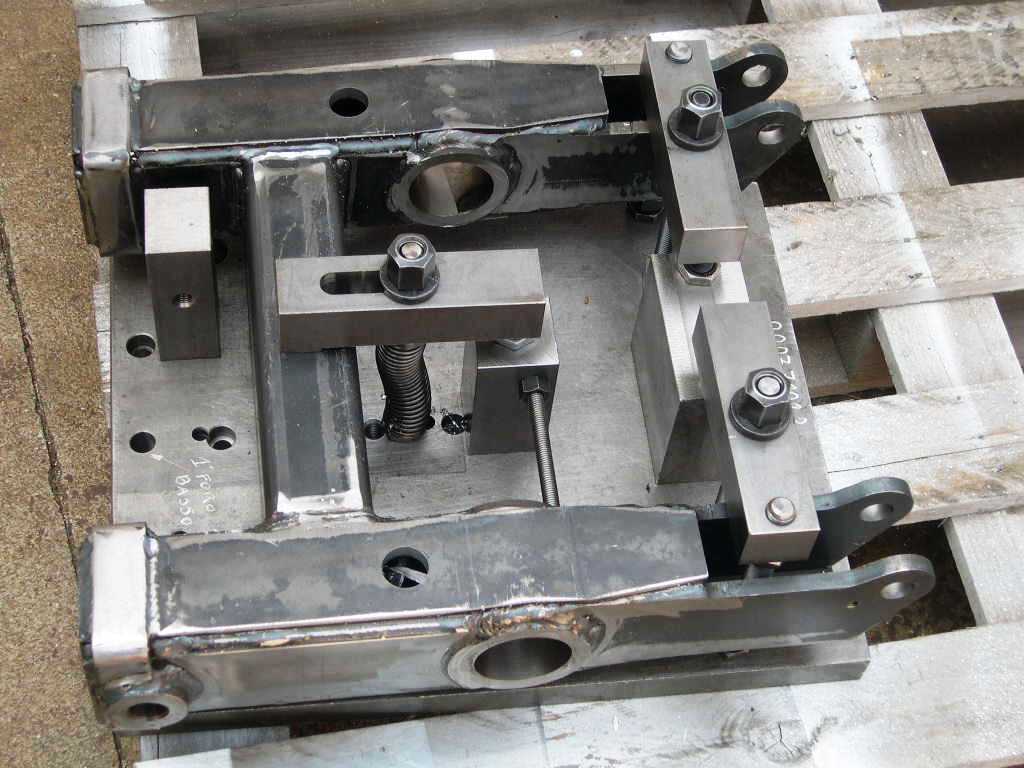

For complex shapes (which cannot be folded) or for large production batches, we adopt the cold molding solution.

If necessary, we also take care of the design and construction of the necessary molding equipment.

Photo Gallery