Design and industrialization

With our technical service we support our customers in the design and industrialization of their product.

The support service, totally free, is especially useful for adapting projects to laser tube cutting technology. But also for the bending and calendering of tubes often a consultancy is required where the parameters to be considered are many.

In some cases, however, the design is integral, that is, we deliver the turnkey project to the customer. Successful cases are, for example, gym and home fitness machines.

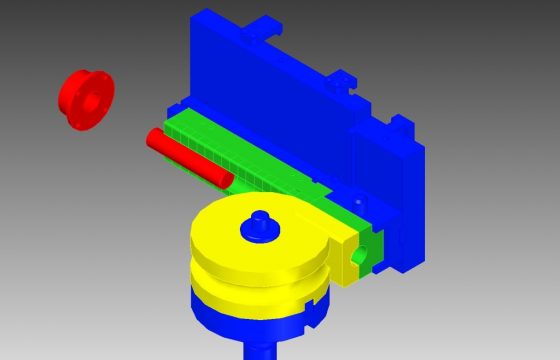

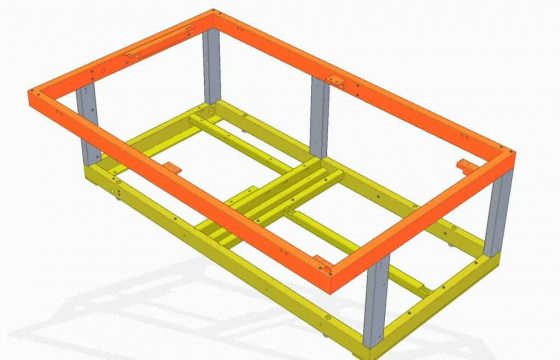

The activity of the technical office, thanks to the know-how acquired, does not stop there. We design production equipment such as welding jigs, bending and bending molds, control gauges, so there is no need to turn to third-party suppliers.

All this translates into a double benefit for the customer. First of all, reducing the time for putting the product into production but above all containing the start-up and industrialization costs of the article itself.

The whole activity is carried out with a three-dimensional CAD software (Siemens Solid Edge) which allows a quick and rapid sharing of the project both towards the customer and towards our production. In fact, in the perspective of what we have been calling Industry 4.0 for years, our projects are directly interconnected with both production machinery and control tools.