Certified welding ISO 3834-3

Department equipped to perform certified welding with different execution techniques. We have 23 manual stations and 2 robotic station.

We can count on qualified operators with licenses and an internal laboratory for the analysis and certification of joints. To find out about our destructive and non-destructive tests, visit our quality page.

The department is certified according to ISO 3834-3

Wire technique (with material addition) used for structural steel for construction (up to S900MC), stainless steel and aluminum alloys. We have 23 workstations and certified operators (license and internal laboratory analysis).

Based on the characteristics of the piece we perform pulsed arc or spray welding.

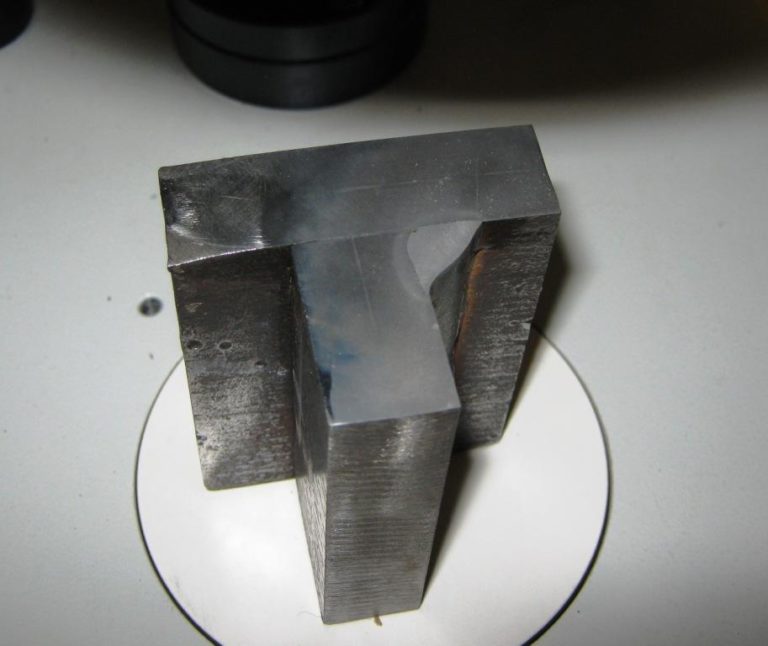

We carry out the TIG welding process, with or without filler material.

TIG welding can also be performed at full penetration and if required with shielding gas (reverse protection).

The more traditional method that we use from time to time, in the face of specific requests from the client.

For the aesthetic and furnishing pieces to complete the welding process we can satin or polish the details themselves.

Photo gallery